What are the Different Parts of a Commercial Wood Door?

A commercial wood door is made up of several key components that work together to provide durability, functionality, and aesthetic appeal. These parts include the core, the faces (skins), the panels, stiles & rails, the edge construction, and the hardware preparations. Understanding each element is essential when selecting a door that meets performance, safety, and design requirements for commercial spaces.

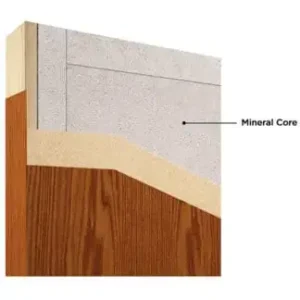

What is the door core?

The door core is the internal structure of a commercial wood door, providing its strength, stability, and performance characteristics. It determines the door’s weight, fire rating, sound insulation, and impact resistance. Common core types include:

- Solid Wood Core – Durable and heavy, offering excellent strength and sound insulation.

- Particleboard Core – Economical and stable, often used in interior applications.

- Mineral Core – Fire-resistant, used in doors requiring fire ratings.

- Honeycomb Core – Lightweight with basic strength, suited for low-traffic areas.

The choice of core depends on the specific functional and safety needs of the building.

What are the door faces (skins)?

Door faces, also known as skins, are the flat outer surfaces of a commercial wood door that cover the core and give the door its finished appearance. These faces are bonded to both sides of the door and play a crucial role in the door’s durability, aesthetics, and performance.

Door faces can be made from a variety of materials, including wood veneer, laminate, medium-density fiberboard (MDF), or hardboard, depending on the desired look and application. Wood veneers offer a natural, high-end appearance, while laminates provide enhanced durability and resistance to scratches, moisture, and wear—ideal for high-traffic commercial settings.

In addition to appearance, door faces may also influence fire rating, impact resistance, and acoustic performance, especially when paired with the right core and edge construction. Ultimately, the choice of door face affects both the function and style of the finished door.

What are the door panels?

Door panels are the individual raised or recessed sections that make up the decorative and structural design of a panel-style door. Unlike flush doors, which have flat, smooth faces, panel doors feature multiple framed sections that add dimension and visual interest. These panels are held in place by stiles (vertical components) and rails (horizontal components), which form the outer framework of the door.

The number and arrangement of panels can vary widely, with common styles including 2-panel, 4-panel, and 6-panel designs. These panels may be square, rectangular, or even arched, depending on the desired aesthetic. In many cases, they serve both a decorative and functional purpose, contributing to the door’s strength and durability.

Door panels are typically made from solid wood, MDF, or other engineered materials. While they are more commonly used in residential or traditional commercial settings, panel doors can also be specified for commercial environments when a more classic or architectural appearance is desired.

What are the door stiles and rails?

Door stiles and rails are the structural framing components found along the edges of a commercial wood door. They play a critical role in reinforcing the door, maintaining its shape, and supporting the installation and function of hardware. These parts surround the door core and help ensure long-term durability and performance, especially in high-use commercial environments.

Stiles are the vertical sections located on the left and right edges of the door. The hinge stile is the side where the hinges are mounted, while the lock stile is where the latch or locking hardware is installed. Stiles are typically constructed with solid wood or reinforced materials to support the stress from repeated opening, closing, and hardware use.

Rails are the horizontal components at the top and bottom of the door. The top rail helps maintain the door’s alignment, while the bottom rail adds weight and structural balance—often designed to meet accessibility standards. Some doors also include a mid-rail, which can provide additional support or aesthetic detail.

Together, stiles and rails create a stable perimeter frame that enhances the door’s strength and helps it withstand daily wear and tear.

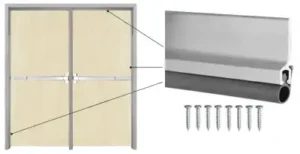

What’s the edge construction of commercial wood doors?

Edge construction refers to the material and design used along the vertical edges of a commercial wood door—specifically the hinge and lock edges. This part of the door is crucial for reinforcing structural integrity, supporting hardware, and preventing damage from frequent use.

The edges are typically constructed with materials like solid hardwood, laminated veneer lumber (LVL), or even steel reinforcements in high-security or fire-rated applications. These materials are bonded to the core and face layers to provide a strong, stable foundation for attaching hinges, locks, closers, or exit devices.

In some cases, doors feature edge banding or protective edge caps, especially in heavy-use areas like schools or hospitals. These can improve durability, resist chipping, and enhance the door’s appearance. Overall, proper edge construction is essential for ensuring a long-lasting, secure, and functional commercial wood door.

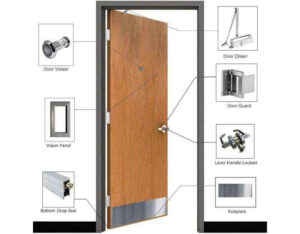

What are the hardware preparations for commercial wood doors?

Hardware preparations for commercial wood doors are the pre-cut or pre-machined areas on the door where hardware components such as hinges, locks, handles, closers, and other accessories will be installed. These preparations ensure that hardware fits precisely and functions properly once mounted.

Typically, hardware preparations include:

- Hinge mortises: Recessed areas on the hinge stile to allow hinges to sit flush with the door edge.

- Lock and latch cutouts: Openings on the lock stile to accommodate locksets, deadbolts, or panic devices.

- Strike plate mortises: Recessed spaces on the door frame or door edge to fit strike plates for locks and latches.

- Prep for door closers and exit devices: Machined areas on the top or face of the door for installing closers or panic hardware.

Proper hardware preparation is critical in commercial doors to ensure smooth operation, security, and compliance with building codes and accessibility standards. These cutouts are usually done during manufacturing but can also be customized to match specific hardware requirements.

If you are in need of wood doors, take a look & get a quote here: Commercial Wood Doors

If you have any additional questions about commercial wood doors, email us at [email protected] or give us a call at 800-685-7541 and we’ll be happy to help you out!