What Are The Components of a Commercial Metal Door Frame?

A commercial metal door frame typically consists of several key components: the frame itself, usually made of steel or other durable metals; jambs, which are the vertical sides of the frame that hold the door in place; the head, the horizontal top section of the frame; and the sill or threshold, which is the bottom part that helps seal the door. Additionally, the frame includes reinforcements to support hardware like hinges, locks, and closers. The frame may also feature a stop to prevent the door from swinging too far, along with anchors for securing the frame to the wall structure. These components work together to provide strength, durability, and proper alignment for the door system.

What are the key components of a commercial metal door frame?

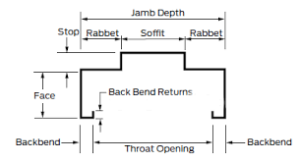

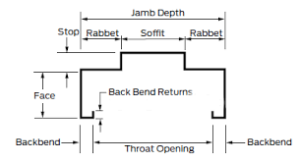

Face: The “face” of a metal door frame refers to the visible side of the frame that is exposed to the room or hallway. It’s the part you see when looking at the door. This face can vary in design and thickness depending on the specific type of frame and its intended use. The specific design of the face can influence the overall aesthetics of the door and frame, as well as its functionality and durability.

Jambs: The vertical sides of the frame (known as the Strike Jamb and the Hinge Jamb) that hold the door in place and provide structural support.

Head: The horizontal top section of the frame, which connects the jambs and provides overall stability.

Sill/Threshold: The bottom part of the frame, often used to seal the door and prevent debris or water from entering the building. It can also aid in providing a tight fit.

Throat: The “throat” of a commercial metal door frame is the opening between the back bends of the frame. It’s the space where the door swings and closes. The size of the throat is crucial as it determines the thickness of the wall material that can be accommodated. Understanding the throat size is essential when selecting a door frame to ensure proper installation and functionality.

Reinforcements: Metal reinforcements embedded in the frame, which provide added strength and support for hardware such as hinges, locks, and closers.

Stop: The stop of a commercial metal door frame is the part that the door edge contacts when it’s closed. It’s typically a piece of metal that is attached to the jambs and head of the frame. The stop ensures that the door closes securely and tightly against the frame, preventing drafts and improving energy efficiency. The stop is an important component of a commercial metal door frame, as it contributes to the overall performance and durability of the door system.

Anchors: These are used to secure the frame to the wall structure, ensuring a secure installation.

Rabbet: A rabbet in a metal door frame is a groove or channel cut into the edge of the frame. This groove is designed to accommodate the edge of the door, ensuring a tight and secure fit. Rabbets can be found on both the jambs and the head of the frame. The size and depth of the rabbet will vary depending on the thickness of the door and the specific requirements of the installation.

Soffit: The soffit of a metal door frame is the area between the two rabbets. It’s the flat part of the frame that runs parallel to the jamb depth. The size of the soffit is determined by the jamb depth and the size of the rabbets. A larger soffit can accommodate thicker wall materials, while a smaller soffit is suitable for thinner walls.

All of these components work together to provide strength, durability, and proper alignment for the door, while allowing it to function effectively within the building’s security and safety requirements.

What materials are commercial metal door frames made from?

Commercial metal door frames are most commonly made from steel, specifically galvanized steel, which is steel coated with zinc and then heat-treated to create a durable, corrosion-resistant surface ideal for painting. This makes it a popular choice for commercial and institutional settings due to its strength, longevity, and resistance to rust.

In some applications, frames may also be made from stainless steel for added corrosion resistance, especially in environments with high moisture or hygiene requirements, like hospitals, laboratories, or coastal buildings. Aluminum frames are another option, typically used in lighter-duty applications or where a modern, architectural look is desired.

Each material is selected based on performance needs, environment, aesthetics, and code requirements.

What are the different types of metal door frames?

There are several types of metal door frames used in commercial construction, each designed to suit different installation needs and building requirements:

- Knocked Down (KD) Frames: These frames are shipped in pieces (jambs and head) and assembled on-site. They’re ideal for renovation projects or locations with limited access, and are typically anchored to drywall or stud walls. KD frames are easy to store, transport, and install.

- Welded Frames: Welded frames are fully assembled at the factory, with the corners welded and ground smooth. They offer greater strength, stability, and are often used in new construction or areas with high traffic. Welded frames are ideal for masonry walls and are quicker to install on-site.

- Slip-On or Drywall Frames: A type of KD frame designed specifically to wrap around drywall partitions. These are commonly used in interior office settings and are easy to install after the wall has been constructed.

- Double Rabbet and Single Rabbet Frames: These describe the profile of the frame. Double rabbet frames can accommodate two doors or a door and sidelight; single rabbet frames are designed for a single door.

Each type of frame is chosen based on factors like wall type, door usage, traffic levels, and whether the project is new construction or a retrofit.

How do I choose between KD and welded frames?

Choosing between Knocked Down (KD) metal door frames and welded metal door frames depends on your project’s needs, installation environment, and performance requirements.

You should consider KD frames if you’re working on a renovation or retrofit project, especially in areas with limited access where transporting a fully assembled frame would be difficult. KD frames come in pieces (jambs and head) and are assembled on-site, making them easier to store and move through tight spaces. They’re ideal for lightweight or drywall partitions and are typically installed after the walls are up, offering flexibility in scheduling and construction.

On the other hand, welded frames are best for new construction, particularly when using masonry walls. These frames are fully assembled with welded corners, providing greater strength, durability, and a clean, seamless appearance. They’re ideal for high-traffic or high-security areas such as schools, hospitals, and public facilities. Welded frames also allow for faster installation on-site since they arrive ready to install.

In summary, KD frames are great for flexibility and ease of transport, while welded frames offer superior strength and stability. The right choice depends on your building type, wall construction, and overall project goals.

What are the standard sizes for commercial metal door frames?

Standard sizes for commercial metal door frames are designed to accommodate common door dimensions and building requirements. Most commercial frames are built to fit the following standard door sizes:

- Widths: 2’0″ (24″), 2’6″ (30″), 3’0″ (36″), and 4’0″ (48″)

- Heights: 6’8″ (80″), 7’0″ (84″), and 8’0″ (96″)

The frame’s throat or jamb depth, which matches the wall thickness, is also standardized but can be customized. Typical jamb depths range from 4-7/8″ for standard drywall to 8-3/4″ or more for masonry or multi-layered wall systems.

While these sizes cover the majority of commercial applications, custom sizes are also available to accommodate unique architectural requirements, oversized doors, or specialized openings like double doors, sidelites, and transoms. Always check local building codes and project specifications when selecting frame dimensions.

What are the key measurements of a commercial metal door frame?

Jamb Depth: This is the overall depth of the frame, including the face and the backbend. Common depths include 4-3/4″, 5-3/4″, 6-3/4″, 7-1/4″, 7-3/4″, 8-1/4″, and 8-3/4″.

Throat Size: This is the opening between the back bends of the frame, where the door swings. Common throat sizes include 3-3/4″, 4-3/4″, 5-1/4″, 6-1/4″, 6-3/4″, 7-1/4″, 7-3/4″, and 8-1/4″.

Frame Width and Height: These dimensions determine the size of the door that can be installed in the frame. Standard sizes include 36″ x 80″, 32″ x 80″, and 30″ x 80″.

Rabbet Depth: This is the depth of the groove in the frame that the door edge fits into. It ensures a tight seal and secure fit.

Soffit Width: This is the width of the flat part of the frame between the two rabbets.

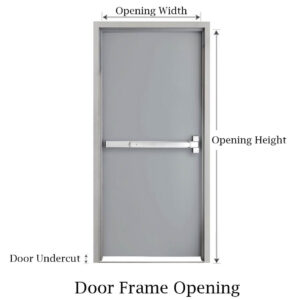

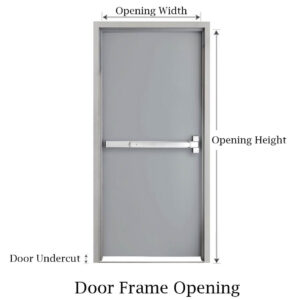

Door Opening: A door frame opening measurement refers to the rough opening dimensions required to install a door frame. This involves measuring the width and height of the opening in the wall where the door will be installed.

Door Width: The door frame width refers to the width of the opening within the door frame. This is the space where the door swings open and closed. When choosing a door frame, it’s crucial to consider the rough opening width, which is the opening in the wall where the door frame will be installed. This rough opening should be slightly larger than the door frame to allow for proper installation and adjustment.

Door Height: The standard height for a door frame in most American homes is 80 inches, or 6 feet 8 inches. This is the most common height for both interior and exterior doors. When choosing a door frame, it’s crucial to consider the rough opening height, which is the opening in the wall where the door frame will be installed. This rough opening should be slightly larger than the door frame to allow for proper installation and adjustment.

Undercut: Door frame undercut measurement refers to the distance between the bottom of the door and the bottom of the frame. This measurement is crucial when installing new flooring, as it ensures the door can still swing open and close smoothly after the floor level is raised. Typically, a 3/4-inch undercut is sufficient for most flooring installations. However, the exact measurement may vary depending on the thickness of the new flooring material.

It’s important to note that these measurements can vary depending on the specific type of frame and the manufacturer. Always consult the manufacturer’s specifications or a professional installer to ensure accurate measurements and proper installation.

If you are in need of commercial metal door frames, take a look at our many options & get a quote here: Commercial Metal Door Frames

If you are also in need of commercial doors, take a look here: Commercial Doors

If you have any additional questions about commercial doors or door frames, email us at [email protected] or give us a call at 800-685-7541 and we’ll be happy to help you out!